Wet scrubbers are critical components in many industrial processes that manage air pollution. They effectively remove dangerous contaminants from gas streams, making them an essential instrument for managing air quality and protecting environmental health. This tutorial gives a thorough overview of wet scrubbers, including their functioning, components, kinds, and uses.

Introduction to Wet Scrubbers

Wet scrubbers are air pollution control systems that employ a liquid (often water) to absorb and remove contaminants from industrial exhaust gasses. These contaminants might include particulate particles, gasses, and even volatile organic compounds (VOCs). Wet scrubbers are often employed in sectors such as chemical processing, metal polishing, mining, and energy generating.

How Wet Scrubbers Work

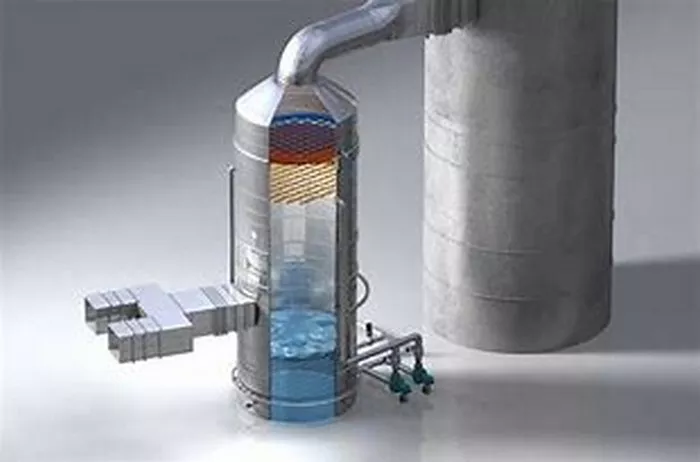

Wet scrubbers operate on the principle of absorption and/or adsorption, depending on the type of pollutants being targeted. The basic components of a wet scrubber include:

1. Inlet/Outlet: The gas stream carrying pollutants enters the scrubber through an inlet and exits through an outlet after treatment.

2. Spray Nozzles: These nozzles disperse the scrubbing liquid into the gas stream, creating a contact area where pollutants are captured.

3. Scrubbing Section: This is where the actual gas-liquid contact occurs. Pollutants are absorbed or adsorbed into the liquid, effectively removing them from the gas stream.

4. Mist Eliminator: After the gas stream passes through the scrubbing section, a mist eliminator removes any liquid droplets carried over from the scrubbing process, ensuring that only clean gas exits the scrubber.

5. Outlet Stack: Clean gas is discharged through an outlet stack, meeting environmental regulations.

The efficiency of a wet scrubber depends on various factors, including the design of the scrubber, the properties of the pollutants and the scrubbing liquid, and the contact time between the gas and the liquid.

Types of Wet Scrubbers

Wet scrubbers come in several configurations, each suited to different applications and pollutant types. Some common types include:

1. Venturi Scrubbers: These scrubbers use the Venturi effect to create a high-velocity zone where the gas and liquid mix, facilitating pollutant capture.

2. Packed Bed Scrubbers: Packed bed scrubbers contain a packing material (such as plastic or metal) that provides a large surface area for gas-liquid contact. Pollutants are absorbed into the liquid as they pass through the packed bed.

3. Spray Tower Scrubbers: In spray tower scrubbers, the gas stream passes through a tower while the scrubbing liquid is sprayed from the top. The droplets capture pollutants as they fall through the tower.

4. Wet Electrostatic Precipitators (WESP): WESPs use an electric field to charge particles in the gas stream, which are then captured by a liquid spray.

5. Fluidized Bed Scrubbers: These scrubbers use a fluidized bed of solid particles to facilitate gas-liquid contact, enhancing pollutant removal efficiency.

Choosing the appropriate type of wet scrubber depends on factors such as the type and concentration of pollutants, gas flow rate, available space, and operating costs.

Applications of Wet Scrubbers

Wet scrubbers find applications in various industries where emissions control is critical. Some common applications include:

1. Chemical Processing: Wet scrubbers are used to remove acidic gases, such as sulfur dioxide (SO2) and hydrogen chloride (HCl), from chemical process exhaust streams.

2. Metal Finishing: Industries involved in metal plating and finishing utilize wet scrubbers to control emissions of metal particulates and volatile organic compounds (VOCs).

3. Mining: In mining operations, wet scrubbers are employed to control dust emissions, particularly from processes such as crushing and grinding.

4. Power Generation: Power plants often use wet scrubbers to remove sulfur dioxide (SO2) and other pollutants from flue gases produced by burning fossil fuels.

5. Waste Incineration: Wet scrubbers play a crucial role in controlling emissions from waste incinerators by capturing particulate matter and harmful gases.

Advantages and Limitations

Wet scrubbers offer several advantages over other pollution control technologies, including:

1. High Efficiency: Wet scrubbers can achieve high removal efficiencies for a wide range of pollutants.

2. Versatility: They can handle varying gas flow rates and pollutant concentrations.

3. Low Maintenance: Many wet scrubber designs have relatively low maintenance requirements compared to other control technologies.

However, wet scrubbers also have some limitations:

1. Water Usage: Wet scrubbers consume large amounts of water, which can be a concern in areas with water scarcity.

2. Chemical Handling: Depending on the pollutants being treated, wet scrubbers may require the handling of corrosive or hazardous chemicals.

3. Energy Consumption: Some types of wet scrubbers consume significant amounts of energy, particularly if they involve processes such as air compression or pumping.

Conclusion

Wet scrubbers are vital equipment for reducing air pollution in a variety of industrial operations. By efficiently eliminating contaminants from gas streams, they contribute to environmental compliance and human health. Understanding the operating principles, kinds, and uses of wet scrubbers is critical for companies seeking efficient pollution control solutions. As environmental standards change, wet scrubbers are expected to remain vital in the pursuit of cleaner air and a healthier environment.